Professor: Supply Chain Management Can Strengthen Connecticut’s Vital Manufacturing Sector

Connecticut’s manufacturing sector remains a powerful economic engine, supporting thousands of jobs and driving innovation in aerospace, defense, health care, and beyond.

Last year, the state’s manufacturers generated more than $34 billion in output, approximately 12% of the state’s gross state product. Connecticut is home to more than 4,500 manufacturing companies and more than 153,000 people work in the industry in our state, according to the latest data.

Yet, manufacturers are navigating unprecedented complexity — rising costs, shifting trade policies, workforce shortages, and fast-changing technologies.

Supply chain management (SCM) provides tools and strategies to turn these challenges into opportunities, according to associate professor Tao Lu of the Operations and Information Management Department at the School of Business. Lu is also the academic director of a new master’s program in supply chain management that began this fall.

New England is considered a “hot spot” for the profession. In Connecticut, the demand for supply-chain managers has increased 52% in the last five years. October is National Manufacturing Month, which highlights the importance of the industry.

Tao recently spoke to UConn Today about how manufacturing can remain robust.

Q: In a recent Connecticut manufacturing survey, 95% of manufacturers reported rising costs. How can supply chain management help them stay competitive?

Lu: Supply chain management provides a holistic approach to optimizing resources and processes across the entire value chain — from upstream suppliers and production facilities to distribution centers and downstream customers. A range of SCM tools can help manufacturers manage rising costs.

For example, inventory optimization tools help minimize cost while ensuring sufficient materials and products to meet demand. Lean practices focus on eliminating waste — such as unnecessary steps, delays, or excess inventory — so that every part of the process adds value. Sales and operations planning helps companies match production capacity with demand forecasts and sales strategies, aligning teams across different functions. Total cost analysis provides a big-picture view of where money is really going. Instead of simply comparing unit prices, it uncovers hidden savings in sourcing, transportation, warehousing, and inventory management.

With this broader perspective, manufacturers can make better trade-offs and protect their margins even in a high-cost environment. As a notable example, Deere & Company, a leading manufacturer of heavy equipment including the John Deere brand, achieved an inventory reduction of $1 billion and annual transportation cost savings of around 5% through end-to-end optimization of its supply chain.

Q: With 66% of state manufacturers citing negative impacts from tariffs and trade policy shifts, how can SCM help manufacturers manage risk and improve responsiveness?

Lu: Manufacturing firms often depend on overseas suppliers for the raw materials and components they need. That reliance also makes them vulnerable when tariffs shift or trade policies change. SCM equips manufacturers with tools to strengthen the resilience of their networks and manage risks before disruptions occur.

One important strategy is supplier diversification — building a broader base of suppliers across multiple regions to avoid over-reliance on any single country. Some firms are also turning to onshoring or nearshoring, which can reduce exposure to geopolitical shocks and shorten lead times.

For example, General Motors announced a $4 billion investment to shift some of its production from Mexico to U.S. plants by 2027, aiming to mitigate tariff risks and strengthen supply-chain resilience. Together, these approaches make supply chains more adaptive and better prepared for rising policy uncertainty.

More broadly, SCM emphasizes collaboration across different organizations that make up a supply chain. By sharing information and aligning incentives, companies can replace siloed, fragmented decisions with a unified and proactive strategy, making the entire network more responsive and better able to adapt to change.

Q: With 82% of state manufacturers reporting difficulty finding and retaining workers, how can SCM help them operate effectively?

Lu: SCM helps companies use their workforce more strategically and sustain productivity even with limited labor resources. Aggregate planning aligns staffing levels with production needs, while process analysis identifies bottlenecks where labor shortages constrain throughput. Advanced scheduling and logistics optimization tools improve how labor is allocated across shifts, production lines, and transport operations — ensuring the right people are in the right place at the right time. Additionally, robotics and automation may take over repetitive or routine tasks to free scarce skilled workers for higher-value roles.

Walmart recently announced plans to open five automated distribution centers to boost productivity with a smaller workforce. However, implementing these technologies requires fundamental knowledge of supply chain and logistics operations.

Q: With only 27% of manufacturers here integrating AI or digital tools, how can SCM guide technology adoption?

Lu: Successful digital adoption begins with a solid SCM foundation — understanding how materials, information, and finances flow across the entire supply chain. Equally important is ensuring that technology choices align with business strategy. SCM provides a framework for companies to decide whether to pursue a responsive strategy focused on speed and flexibility, or an efficient strategy centered on cost and optimization. The right digital tools should support that strategic fit, turning technology investments into meaningful operational advantages.

Q: Why do you think adoption has been so slow?

Lu: Change management takes time because transforming processes, training people, and building organizational trust is often harder than implementing the technology itself. At the same time, AI governance remains complex, requiring firms to ensure data quality, safeguard data security and privacy, and uphold ethical standards across the supply chain.

Q: Who would make a great supply-chain manager? And what are some of the most rewarding aspects of the job?

Lu: A great supply chain manager is both analytical and people oriented. They understand how to optimize resources and processes across the supply chain, but they’re also skilled at communicating insights and leading collaboration across departments – from operations and finance to marketing – and with external partners and stakeholders throughout the value chain.

A business background is not a requirement for entering our master’s degree program. In fact, many successful supply-chain leaders come from diverse fields such as engineering, analytics, or economics.

In my view, one of the most rewarding aspects of being a supply-chain professional is the integrative nature of the work. You manage the movement of materials, information, and money — the three flows that define how a company operates and creates value. This broad view of how businesses function provides the opportunity to make a tangible impact on efficiency, sustainability, and innovation.

Tao Lu is an associate professor in the Department of Operations and Information Management. He is also the academic director of the new master’s program in Supply Chain Management. Lu’s research focuses on supply chain management, transport logistics, gig economy platforms and socially responsible operations.

Latest UConn Today

- Meet Jean: A Lifetime Giver on a Mission to Always Help OthersJean Martin has enrolled in a new UConn Health clinical research study to help enhance the future care of sickle cell disease patients.

- Misunderstood Monsters: Tales of Horror Are Far More Than Blood Splatter and Gore'There’s just tremendous beauty and art and intelligence behind the greatest films in any category. Why do so many critics plug in the worst horror films for all horror?'

- UConn John Dempsey Hospital Recognized for Exceptional Clinical PerformanceSepsis, pneumonia, hip fracture care, and GI surgery earn 5 stars from Healthgrades

- Being Seen, Feeling Seen: Summit Examined Complicated, Far-Ranging Intersections of Sport and Human RightsHuman Rights Summit features perspectives from athletes, academics, and industry experts

- Protein Powders and Shakes Contain High Amounts of Lead, New Report Says – A Pharmacologist Explains the DataPowder and ready-to-drink protein sales have exploded, reaching over US$32 billion globally from 2024 to 2025. Increasingly, consumers are using these protein sources daily.

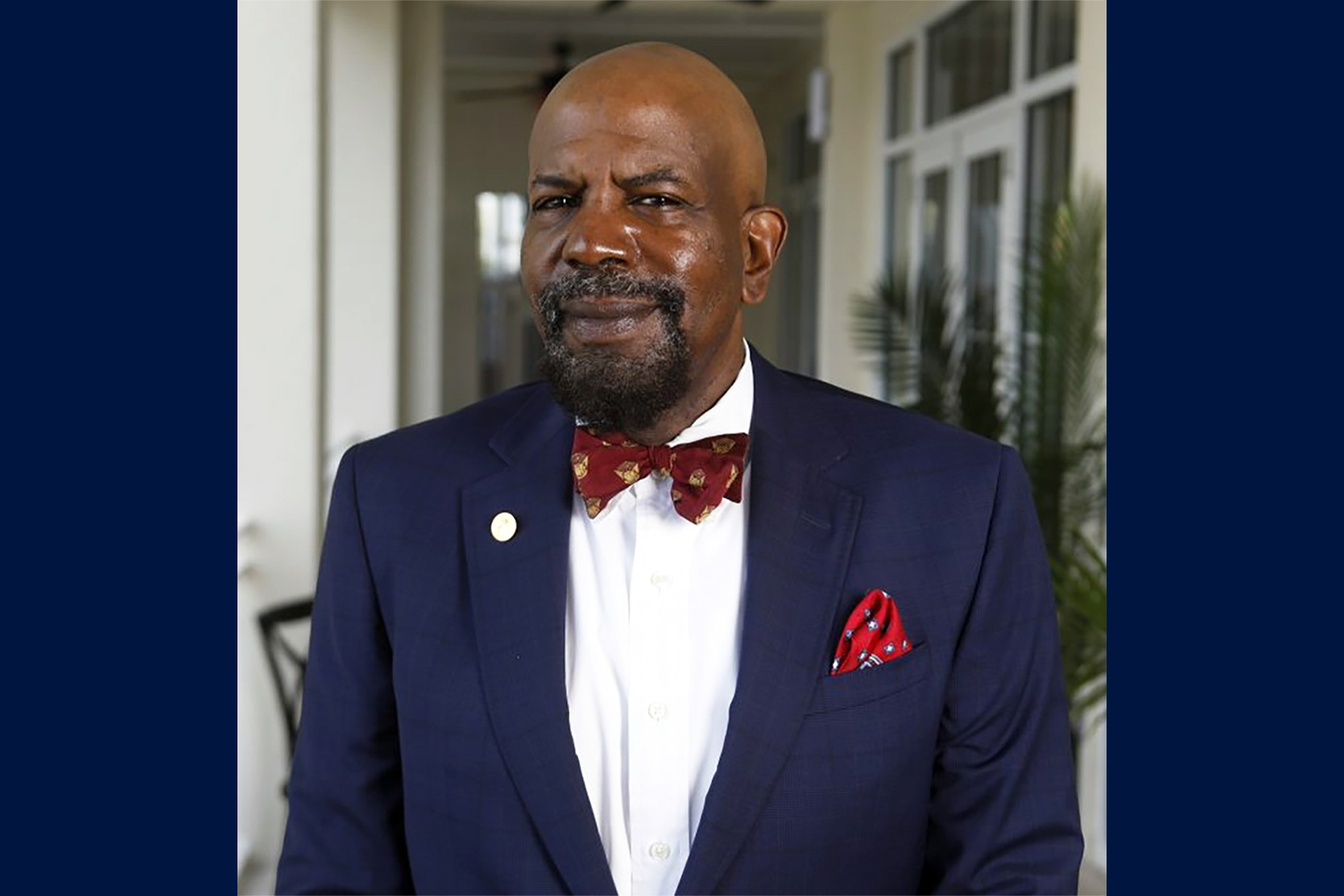

- Professor Sir Cato T. Laurencin is Plenary Speaker at AAMP ConferenceUConn Professor Sir Cato T. Laurencin was the Plenary Speaker at 39th Annual Association for Academic Minority Physicians, Inc. Conference in Alexandria, VA.